Induction Motor: Working Principles, Types, Applications & Top Manufacturers in India (2025)

Team IEC

- 1

Induction Motor: Working Principles, Types, Applications & Top Manufacturers in India (2025)

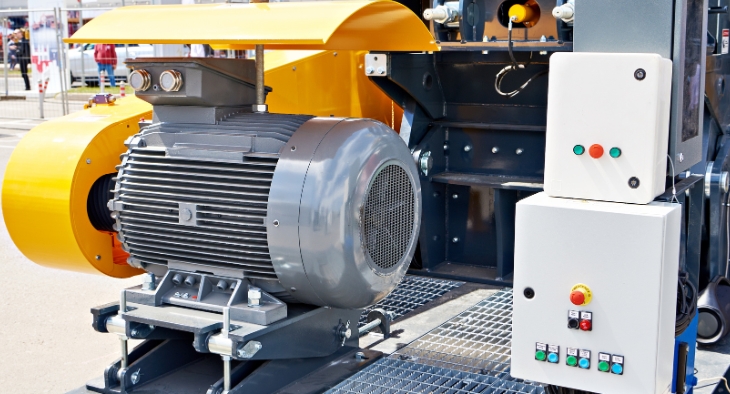

In today’s rapidly evolving industrial landscape, the induction motor remains a cornerstone of both heavy industry and everyday applications. As India continues its journey toward industrial modernization and energy efficiency, understanding the working principles, types, applications, and leading manufacturers of induction motors is more crucial than ever. This comprehensive guide explores every facet of induction motors—from the fundamentals to cutting-edge innovations—to help you make informed decisions whether you’re an engineer, a student, or an industry professional.

1. What is an Induction Motor?

An induction motor is an electromechanical device that converts electrical energy into mechanical energy through the process of electromagnetic induction. First popularized in the late 19th and early 20th centuries, these motors have become ubiquitous due to their robust construction, simplicity, and cost-effectiveness.

Key Characteristics:

- Robust Design: Fewer moving parts mean less maintenance.

- Cost Efficiency: Generally less expensive than other types of motors.

- Versatility: Suitable for a wide range of applications from small appliances to heavy industrial machinery.

- Durability: With proper care, these motors have a long operational lifespan.

In India, induction motors power critical sectors such as manufacturing, agriculture, and domestic appliances, contributing significantly to the nation’s economic development.

2. How Does an Induction Motor Work?

The core principle behind an induction motor is electromagnetic induction. Here’s a step-by-step breakdown of its operation:

- AC Supply and the Stator: The motor’s stator is connected to an alternating current (AC) supply. This current creates a rotating magnetic field around the stator.

- Induction in the Rotor: The rotating magnetic field passes through the air gap and induces an electromotive force (EMF) in the rotor conductors. This phenomenon is based on Faraday’s law of electromagnetic induction.

- Rotor Currents and Torque Production: The induced currents in the rotor generate their own magnetic fields. These fields interact with the stator’s magnetic field, creating a force (torque) that causes the rotor to turn.

- Slip: The rotor does not reach the same speed as the rotating magnetic field—a difference known as “slip.” This slip is essential for continuous torque generation and stable operation.

3. Types of Induction Motors

Induction motors are primarily categorized into two types, each with its distinct design and application nuances:

A. Squirrel Cage Induction Motors

- Design & Operation: Featuring a rotor made up of laminated iron cores and conductive bars short-circuited by end rings, these motors are renowned for their rugged simplicity and high reliability.

- Applications: Widely used in industrial drives, fans, pumps, and compressors.

- Advantages: Low maintenance, cost-effective, and efficient for continuous operation.

B. Wound Rotor Induction Motors

- Design & Operation: These motors have a rotor wound with insulated wire and connected to external resistances via slip rings, allowing for controlled starting and adjustable speed.

- Applications: Ideal for applications requiring high starting torque or variable speed control, such as in heavy machinery.

- Advantages: Better torque control and lower inrush current during startup.

Comparison at a Glance:

| Feature | Squirrel Cage | Wound Rotor |

|---|---|---|

| Cost | Generally lower | Slightly higher |

| Maintenance | Minimal | Requires additional components |

| Starting Torque | Moderate | High (with external resistances) |

| Applications | General industrial and domestic | Heavy machinery, variable speed drives |

4. Applications of Induction Motors in India

Induction motors are indispensable across a variety of sectors in India:

Industrial Sector

- Manufacturing: Drive systems in assembly lines and machine tools.

- Textiles & Food Processing: Efficiently powering conveyors, mixers, and pumps.

- Mining and Extraction: Robust motors for heavy-duty applications in extraction industries.

Commercial and Domestic Use

- HVAC Systems: Ventilation and air conditioning systems in residential and commercial buildings.

- Household Appliances: Washing machines, fans, and refrigerators.

- Water Pumping: Agricultural irrigation systems and municipal water supply.

5. Top Manufacturers of Induction Motors in India (2025)

As of 2025, several manufacturers stand out in the Indian market for their innovation, quality, and customer support:

1. Siemens India

- Overview: Siemens provides innovative industrial solutions, including induction motors that emphasize precision and control.

- Key Offerings: Motors engineered for demanding environments, featuring smart diagnostics and IoT connectivity.

2. CG Power & Industrial Solutions (Formerly Known as Crompton Greaves)

- Overview: A pioneer in electrical engineering, Crompton Greaves offers a wide range of induction motors known for their durability and energy efficiency.

- Key Offerings: High-performance motors for industrial applications with robust after-sales service.

3. ABB India

- Overview: ABB is a global leader in power and automation technologies, with a strong presence in India.

- Key Offerings: Advanced induction motors integrated with digital solutions for performance monitoring and energy management.

4. Bharat Bijlee

- Overview: Bharat Bijlee is a renowned Indian company specializing in electrical engineering and manufacturing, with a significant footprint in the power transmission and distribution sector.

- Key Offerings: High-efficiency transformers and motors, complemented by innovative digital solutions for enhanced operational efficiency and energy optimization.

5. Kirloskar Electric Company

- Overview: With decades of experience, Kirloskar Electric Company offers robust induction motors tailored for the Indian market.

- Key Offerings: Motors designed for efficiency and reliability, widely used in agricultural and industrial applications.

These manufacturers continuously innovate to meet the evolving demands of energy efficiency, automation, and industrial performance in India.

6. Advantages and Limitations

Advantages

- Simplicity and Reliability: Fewer moving parts reduce the risk of mechanical failure.

- Cost-Effective: Generally lower initial and maintenance costs.

- Robust Construction: Suitable for harsh industrial environments.

- Energy Efficiency: High efficiency under load conditions, contributing to energy savings.

Limitations

- Starting Torque: Some induction motors, particularly the squirrel cage type, may have lower starting torque.

- Control Complexity: Fine-tuning performance in applications requiring variable speeds might require additional controllers or the use of wound rotor designs.

- Heat Dissipation: Continuous operation at high loads may lead to thermal challenges if not properly maintained.

7. Energy Efficiency and Performance Optimization

Energy efficiency is a significant consideration, especially in India’s context of increasing energy costs and environmental concerns.

Strategies for Optimization:

- Proper Load Management: Operate motors close to their optimal load capacity to reduce energy wastage.

- Regular Maintenance: Routine inspections and cleaning of components (e.g., ventilation fans and bearings) ensure smooth operation and prevent overheating.

- Advanced Control Systems: Utilizing variable frequency drives (VFDs) can help optimize motor speed and reduce energy consumption.

- Upgrading Technology: Adoption of smart sensors and IoT integration facilitates real-time monitoring and predictive maintenance.

Implementing these strategies not only improves performance but also aligns with India’s national energy efficiency initiatives.

8. Installation, Maintenance, and Troubleshooting

Ensuring a long and efficient service life for your induction motor involves adherence to best practices in installation and maintenance:

Installation Best Practices:

- Accurate Alignment: Ensure the motor is precisely aligned with the driven equipment to prevent undue stress.

- Proper Ventilation: Install in areas with adequate airflow to mitigate heat buildup.

- Secure Mounting: Use appropriate mounting methods to reduce vibration and mechanical stress.

Maintenance Tips:

- Regular Inspections: Schedule periodic checks for wear and tear, particularly on bearings and insulation.

- Lubrication: Maintain lubrication of moving parts as recommended by the manufacturer.

- Cleaning: Keep the motor and its surrounding area free from dust and debris.

Troubleshooting Common Issues:

- Overheating: Check for ventilation blockages and ensure the motor is not overloaded.

- Unusual Noises: Inspect for bearing failures or misalignment issues.

- Reduced Efficiency: Verify the electrical connections and monitor the motor’s power factor.

Providing step-by-step guides and video tutorials can significantly aid technicians and engineers in diagnosing and resolving common issues.

9. Future Trends and Innovations

The landscape of induction motor technology is evolving rapidly, driven by advances in automation, IoT, and smart manufacturing:

- Smart Motor Controls: Integration with IoT platforms allows for real-time performance monitoring and remote diagnostics.

- Predictive Maintenance: AI-driven algorithms predict potential failures before they occur, minimizing downtime.

- Energy Harvesting Technologies: Future designs may incorporate energy recovery systems to further enhance efficiency.

- Sustainable Materials: Research into eco-friendly materials is likely to lead to motors that are not only efficient but also environmentally sustainable.

These innovations are poised to further transform industries in India, where the demand for smart, energy-efficient solutions is at an all-time high.

10. Frequently Asked Questions (FAQs)

Q1: What distinguishes an induction motor from a synchronous motor?

A: Induction motors operate using electromagnetic induction without the need for external excitation of the rotor, whereas synchronous motors require a separate DC supply to the rotor windings to maintain a constant speed.

Q2: Can induction motors be used for variable speed applications?

A: Yes, especially the wound rotor type. With the addition of variable frequency drives (VFDs), even squirrel cage motors can be adapted for variable speed operation.

Q3: What routine maintenance is recommended for an induction motor?

A: Regular inspections, proper lubrication of bearings, cleaning of ventilation areas, and periodic checks of electrical connections are key to maintaining optimal performance.

Q4: How energy-efficient are modern induction motors?

A: Modern induction motors are designed for high efficiency, especially when operated near their rated load and maintained properly. Integration with VFDs further enhances their efficiency.

Q5: Which factors should be considered when selecting an induction motor for industrial use in India?

A: Consider the motor’s power rating, duty cycle, energy efficiency, ambient conditions, and the reputation of the manufacturer—especially given the local climate and operational challenges.

11. Conclusion

Induction motors have proven their mettle over decades of service in industries and households alike. Their robust design, energy efficiency, and adaptability make them a prime choice for powering India’s modernizing infrastructure. This guide has taken you through the fundamental working principles, various types, diverse applications, and introduced you to some of the top manufacturers leading the industry in 2025.

As you explore or invest in induction motor solutions, remember that proper installation, regular maintenance, and staying abreast of emerging trends are key to leveraging their full potential. Whether you’re looking to upgrade your current systems or embark on a new project, the knowledge shared here is designed to empower you with the insights necessary to succeed in today’s competitive landscape.

Feel free to share your thoughts and questions in the comments below. Stay tuned for more insights into the world of industrial technology and energy solutions in India!

Best