Role of Electric Motors in the Manufacturing Industry

Team IEC

- 1

Role of Electric Motors in the Manufacturing Industry

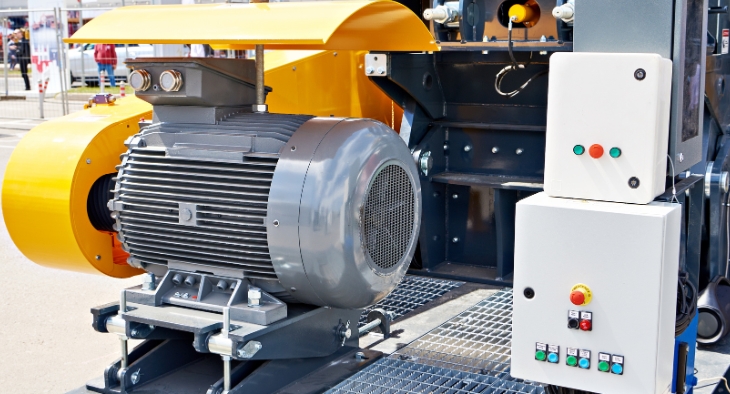

Electric motors are the backbone of the manufacturing industry, powering various machines and processes essential for production. In India, with the rapid growth of industrial sectors such as automotive, textile, pharmaceuticals, and electronics, the demand for reliable and energy-efficient electric motors has surged. This article explores the pivotal role of electric motors in the manufacturing industry, emphasizing their applications, advantages and innovations.

1. Introduction to Electric Motors

Electric motors convert electrical energy into mechanical energy, enabling various machines and devices to perform work. They are indispensable in manufacturing due to their efficiency, reliability, and versatility.

2. Types of Electric Motors Used in Manufacturing

Electric motors in manufacturing come in various types, each suited for specific applications:

| Type of Motor | Characteristics | Applications |

|---|---|---|

| AC Motors | High efficiency, easy to control, and low maintenance | Conveyors, fans, pumps |

| DC Motors | High torque and speed control | Lathes, elevators, and heavy machinery |

| Stepper Motors | Precision control and repeatability | CNC machines, robotics |

| Servo Motors | High accuracy and speed | Packaging machines, robotics, automation |

| Synchronous Motors | Constant speed under varying loads | Large-scale industrial applications |

| Induction Motors | Durable, low-cost, and reliable | Compressors, crushers, and mixers |

3. Applications of Electric Motors in the Manufacturing Industry

Electric motors are integral to numerous manufacturing processes. Some key applications include:

3.1. Material Handling

Electric motors drive conveyor belts, cranes, and hoists, streamlining the movement of raw materials and finished products.

3.2. Machining Processes

Motors power lathes, milling machines, grinders, and drills, ensuring precision in cutting and shaping materials.

3.3. Robotics and Automation

In modern manufacturing, electric motors play a central role in robotic arms and automated guided vehicles (AGVs), enhancing efficiency and accuracy.

3.4. HVAC Systems

Heating, ventilation, and air conditioning systems in factories depend on electric motors for optimal climate control.

3.5. Packaging

Electric motors power packaging machines, ensuring seamless wrapping, labeling, and boxing of goods.

4. Advantages of Electric Motors

- Energy Efficiency: Advanced electric motors consume less power, reducing operational costs.

- Reliability: Their robust design ensures long operational life and minimal downtime.

- Eco-Friendly: Electric motors produce no emissions, contributing to a greener manufacturing environment.

- Low Maintenance: Modern motors require minimal upkeep, saving time and money.

- Versatility: They can be adapted for various speeds and loads, making them suitable for diverse applications.

5. Challenges and Solutions in Electric Motor Usage

5.1. Overheating

Solution: Install temperature monitoring systems and use motors with better cooling mechanisms.

5.2. Energy Consumption

Solution: Upgrade to energy-efficient motors and adopt variable frequency drives (VFDs) for speed control.

5.3. Maintenance Costs

Solution: Opt for motors with predictive maintenance capabilities to reduce unexpected breakdowns.

5.4. Noise and Vibrations

Solution: Use vibration dampers and ensure proper alignment during installation.

6. Recent Innovations in Electric Motors

- Smart Motors: Integration of IoT for real-time monitoring and predictive maintenance.

- Permanent Magnet Motors: Higher efficiency and reduced size.

- Brushless DC Motors: Increased lifespan and lower maintenance requirements.

- Hybrid Motors: Combination of different motor types for enhanced performance.

7. The Role of Energy Efficiency in Electric Motors

Energy efficiency is critical in reducing operational costs and environmental impact. The Indian government has introduced several initiatives, such as the Perform, Achieve, and Trade (PAT) scheme, to encourage industries to adopt energy-efficient technologies, including motors.

8. Government Policies and Support in India

India’s government supports the manufacturing sector through policies like the “Make in India” initiative. Subsidies and tax benefits for adopting energy-efficient motors and equipment further promote sustainable growth.

9. Comparison of Key Electric Motor Brands

| Brand | Key Features | Market Presence in India |

|---|---|---|

| Bharat Bijlee | Energy-efficient motors, extensive service network | Strong |

| Siemens | Advanced technology, global reputation | Robust |

| CG Power | Cost-effective, reliable motors | Widespread |

| ABB | Smart motor systems with IoT capabilities | Significant |

| Kirloskar Electric | Durable and efficient motors | Popular |

10. FAQs

1. What are the most common types of electric motors used in manufacturing?

AC motors, DC motors, stepper motors, and induction motors are commonly used, each tailored to specific applications.

2. How do electric motors contribute to energy efficiency in manufacturing?

Modern electric motors consume less energy, reduce wastage, and integrate with energy-saving technologies like VFDs.

3. Why is predictive maintenance important for electric motors?

Predictive maintenance minimizes unexpected breakdowns, extends motor lifespan, and reduces maintenance costs.

4. Which industries in India rely heavily on electric motors?

Automotive, textile, pharmaceuticals, and electronics industries heavily rely on electric motors for their operations.

5. How can manufacturers in India benefit from government policies related to electric motors?

By adopting energy-efficient motors, manufacturers can avail of subsidies, tax benefits, and incentives under schemes like “Make in India” and the PAT program.

best